SS102B CLASS BUSHED STEEL CHAIN

SKU: SS102B

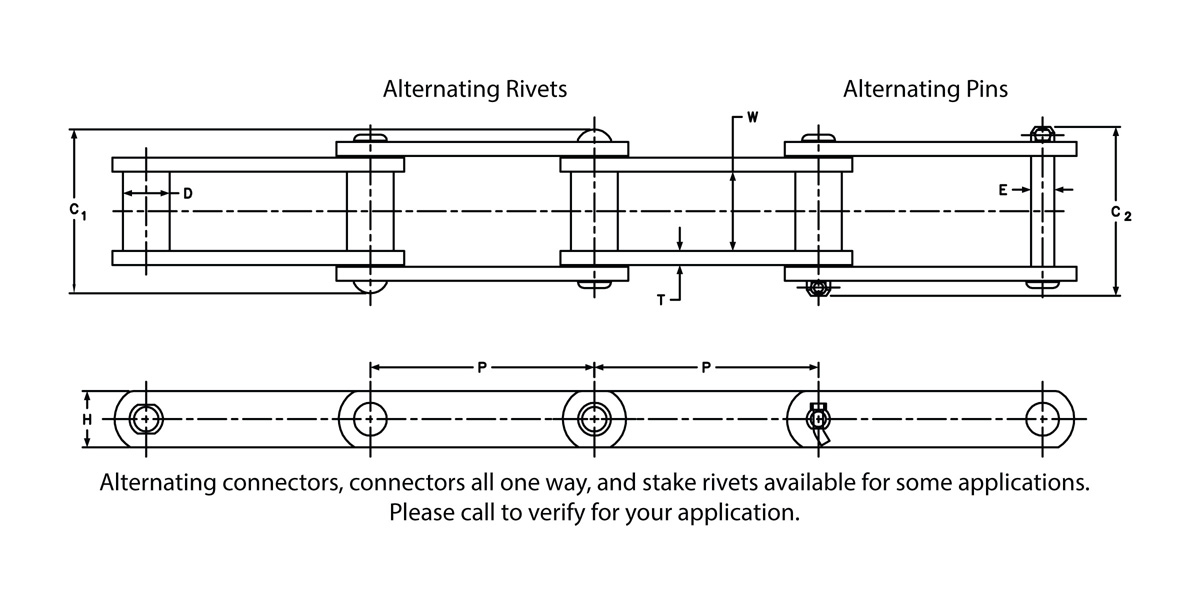

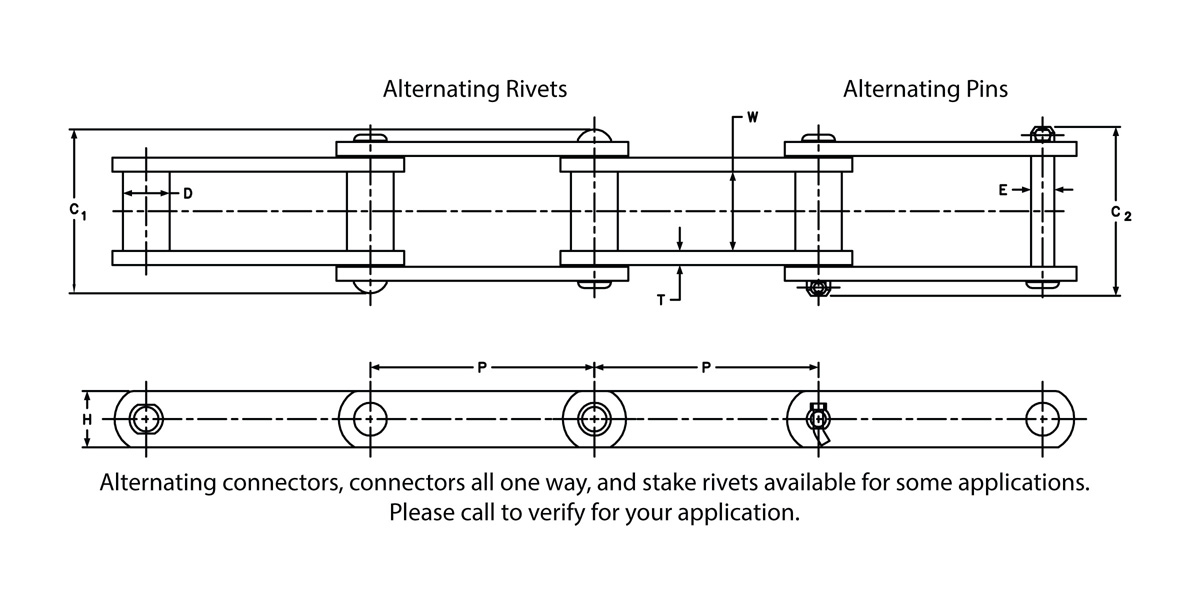

- Pitch 4.000

- Overall Width - Cottered (C2) 4.53

- Diameter of Pin (E) 0.625

- Overall Width - Riveted (C1) 4.38

- Height of Sidebar (H) 1.50

- Diameter of Bushing (D) 1.00

- Head of Pin to Center Line (J) 2.05

- End of Pin to Center Line - Cottered (K) 2.27

- End of Pin to Center Line - Riveted (L) 2.19

- Thickness of Sidebar (T) 0.38

- Distance Between Inner Sidebars (W) 2.12

- Overall Length of Bushing (X) 2.88

- Avg. Ultimate Strength 40,000 lb

- Max. Recommended Working Load 6,300 lb

- Links per 10' 30

- Avg. Weight 6.9 lb/ft

- Pins Alloy Steel, Case Hardened

- Bushings Carbon Steel, Case Hardened

Allied-Locke SS Class Bushed Steel Chain is ideal for operating under extremely gritty or abrasive conditions. This chain is often referred to as "Steel Bushed" or "Rollerless." Each part is machined and heat treated with the result of strength and wear, assuring optimum fit for the pins and bushings. Sidebars are produced to accommodate the ends of the pins which lock into position in the sidebars and will not rotate during operation.

The materials used are carefully selected. The pins are alloy steel that contain nickel, chrome and molybdenum, which improves the chain life through its greater fatigue resistance, improved abrasive resistance, and increased tensile strength at both high and low temperatures. These factors result in a premium product for conveyor and elevator service for gritty, abrasive, and fine particle materials such as ashes, crushed coal, soda ash, cement, crushed stone, and gravel.

The chains are USA made by Allied-Locke and offered to you by farmchains.com. We also offer an assortment of attachments. All of the cottered chain uses T-head cotters. Cottered construction will be supplied unless riveted is requested. Sprockets are also available in cast steel and fabricated when required.

SKU: SS102B

- Pitch 4.000

- Overall Width - Cottered (C2) 4.53

- Diameter of Pin (E) 0.625

- Overall Width - Riveted (C1) 4.38

- Height of Sidebar (H) 1.50

- Diameter of Bushing (D) 1.00

- Head of Pin to Center Line (J) 2.05

- End of Pin to Center Line - Cottered (K) 2.27

- End of Pin to Center Line - Riveted (L) 2.19

- Thickness of Sidebar (T) 0.38

- Distance Between Inner Sidebars (W) 2.12

- Overall Length of Bushing (X) 2.88

- Avg. Ultimate Strength 40,000 lb

- Max. Recommended Working Load 6,300 lb

- Links per 10' 30

- Avg. Weight 6.9 lb/ft

- Pins Alloy Steel, Case Hardened

- Bushings Carbon Steel, Case Hardened

Allied-Locke SS Class Bushed Steel Chain is ideal for operating under extremely gritty or abrasive conditions. This chain is often referred to as "Steel Bushed" or "Rollerless." Each part is machined and heat treated with the result of strength and wear, assuring optimum fit for the pins and bushings. Sidebars are produced to accommodate the ends of the pins which lock into position in the sidebars and will not rotate during operation.

The materials used are carefully selected. The pins are alloy steel that contain nickel, chrome and molybdenum, which improves the chain life through its greater fatigue resistance, improved abrasive resistance, and increased tensile strength at both high and low temperatures. These factors result in a premium product for conveyor and elevator service for gritty, abrasive, and fine particle materials such as ashes, crushed coal, soda ash, cement, crushed stone, and gravel.

The chains are USA made by Allied-Locke and offered to you by farmchains.com. We also offer an assortment of attachments. All of the cottered chain uses T-head cotters. Cottered construction will be supplied unless riveted is requested. Sprockets are also available in cast steel and fabricated when required.

| Type: | |

|---|---|

| Vendor: |

Farmchains.com |

| SKU: |

SS102B |

| Weight: |

68.0 lb |