WH132 WELDED MILL CHAIN

SKU: WH132

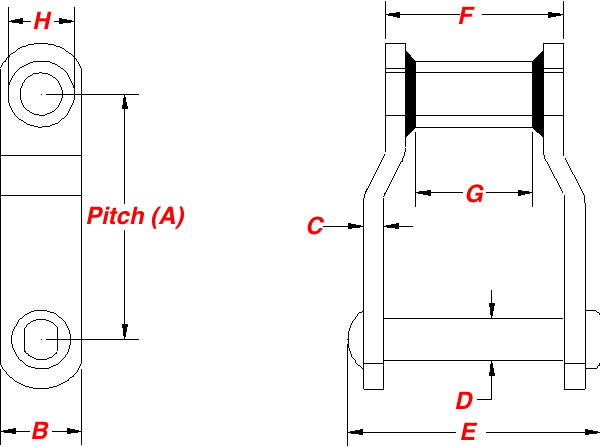

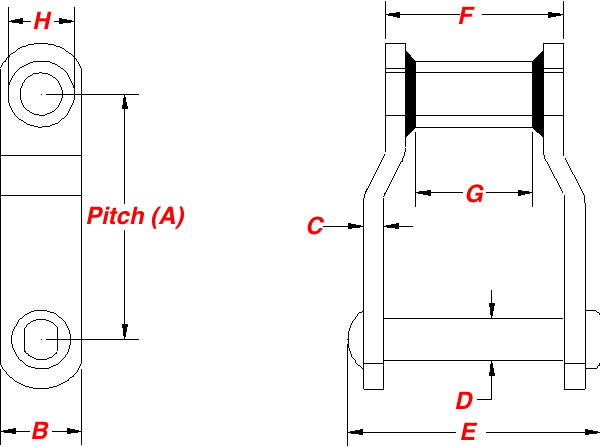

- Pitch (P) 6.050

- Rivet Diameter (D) 1.00

- Side Bar Width (F) 2.00

- Barrel Diameter (H) 1.62

- Max. Sprocket Face (A) 2.88

- Length of Bearing (X) 4.38

- Max. Recommended Working Load 15,300 lb

- Overall Width (JK) 6.25

- Side Bar Thickness (T) .50

- Avg. Ultimate Strength 115,000 lb

- Approx. Links per 10 ft. 20

- Avg. Weight 14.2 lb/ft

WH132 Chain Dimensions

Allied-Locke Made in the USA is a top Engineer-Class chain in the marketplace today, this welded mill chain offers efficiency in various industries. It's perfect for processing pulp, sugar, paper, grain handling, forestry applications, and other heavy-duty conveyance sectors. Interestingly enough WH132 steel chain will run on the same sprockets as it's cast counterpart H132 chain, which makes making the switch to a welded steel chain seamless!

Each mill chain comes as an offset link design with a low 14.2-pounds-per-foot weight specification. With 122,000 pounds of ultra-high tensile strength, this WH132 chain serves your industry well. The secret behind its durability is high-precision strengthened welds added to high-grade steel. Every weld is supported by heat-treated parts that include the barrels, side plates, and pins.

We are a proud supplier of Allied-Locke chain. Allied-Locke has been the leader in providing the highest quality USA made chain on the market today.

WH132 Welded Steel Chain Construction

Welded steel chains got their name from their construction. A welded steel chain is manufactured with a precision strengthened weld around the outside diameter of the barrel connecting the two sidebars together. Within the barrel, there is the pin which on a WH132 chain the pin is full 360° heat-treated for optimal wear life. Then housing it all are the heat-treated distinctive offset style sidebars.

WH132 Chain Application Examples:

- Heavy-duty conveyors

- Forestry

- Grain handling

- Pulp, paper, and sugar processing

SKU: WH132

- Pitch (P) 6.050

- Rivet Diameter (D) 1.00

- Side Bar Width (F) 2.00

- Barrel Diameter (H) 1.62

- Max. Sprocket Face (A) 2.88

- Length of Bearing (X) 4.38

- Max. Recommended Working Load 15,300 lb

- Overall Width (JK) 6.25

- Side Bar Thickness (T) .50

- Avg. Ultimate Strength 115,000 lb

- Approx. Links per 10 ft. 20

- Avg. Weight 14.2 lb/ft

WH132 Chain Dimensions

Allied-Locke Made in the USA is a top Engineer-Class chain in the marketplace today, this welded mill chain offers efficiency in various industries. It's perfect for processing pulp, sugar, paper, grain handling, forestry applications, and other heavy-duty conveyance sectors. Interestingly enough WH132 steel chain will run on the same sprockets as it's cast counterpart H132 chain, which makes making the switch to a welded steel chain seamless!

Each mill chain comes as an offset link design with a low 14.2-pounds-per-foot weight specification. With 122,000 pounds of ultra-high tensile strength, this WH132 chain serves your industry well. The secret behind its durability is high-precision strengthened welds added to high-grade steel. Every weld is supported by heat-treated parts that include the barrels, side plates, and pins.

We are a proud supplier of Allied-Locke chain. Allied-Locke has been the leader in providing the highest quality USA made chain on the market today.

WH132 Welded Steel Chain Construction

Welded steel chains got their name from their construction. A welded steel chain is manufactured with a precision strengthened weld around the outside diameter of the barrel connecting the two sidebars together. Within the barrel, there is the pin which on a WH132 chain the pin is full 360° heat-treated for optimal wear life. Then housing it all are the heat-treated distinctive offset style sidebars.

WH132 Chain Application Examples:

- Heavy-duty conveyors

- Forestry

- Grain handling

- Pulp, paper, and sugar processing

| Type: | |

|---|---|

| Vendor: |

Farmchains.com |

| SKU: |

WH132 |

| Weight: |

142.0 lb |